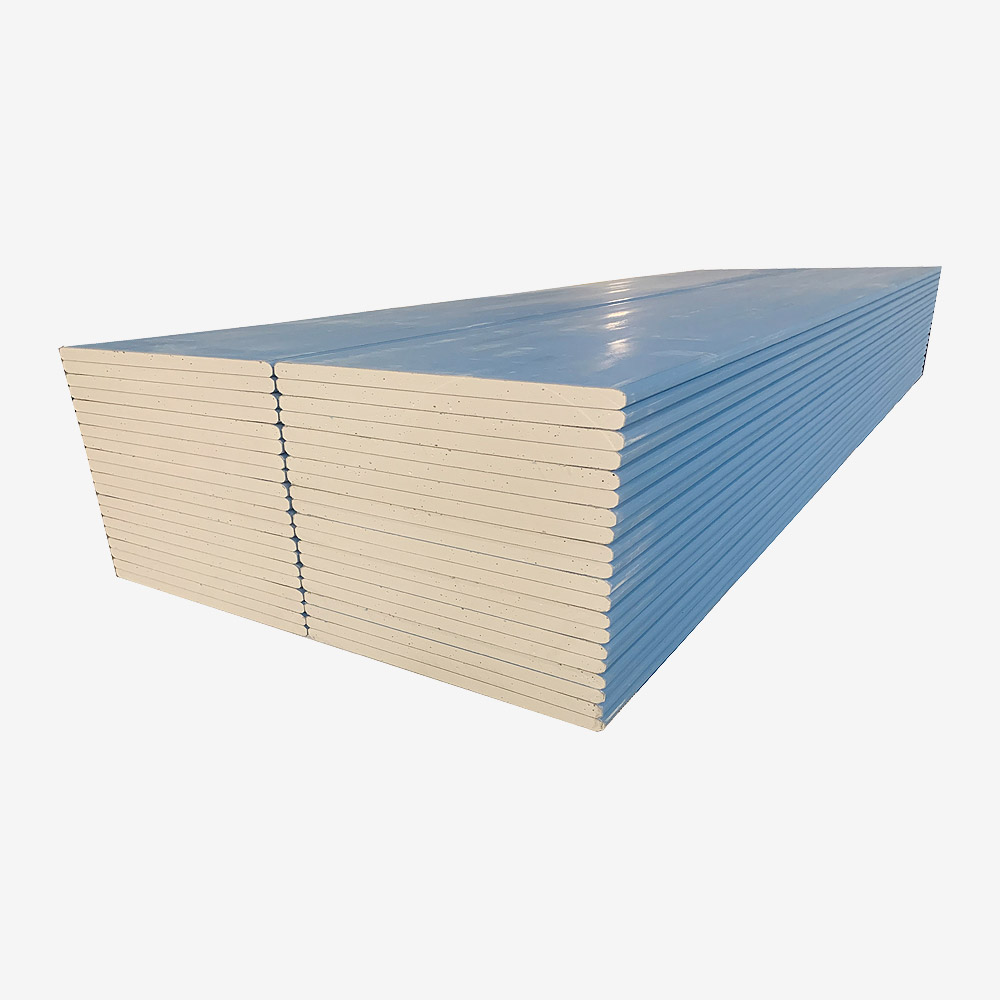

M-BLOC® Shaft Liner Panel

American Gypsum’s 1” M-Bloc® Shaft Liner gypsum panels consist of a fire-resistant type X core that is encased in a mold and moisture resistant blue face and back paper manufactured from 100% recycled paper. The face paper is folded around the long edges to reinforce and protect the core. The panels feature a double beveled edge for ease of installation, with the ends being square-cut and finished smooth. M-Bloc Shaft Liner panels are available: 1” thick x 2’ wide, and in a variety of lengths. At an independent laboratory accredited in accordance with ISO 17025-2005, M-Bloc panels have been tested to the industry’s most rigorous standards achieving the best possible results per ASTM D3273, scoring a perfect 10 thus minimizing the risk of mold and mildew growth.

Basic Uses

M-Bloc Shaft Liner panels are used in conjunction with other American Gypsum products and metal framing members for Shaftwall and Area Separation Wall systems. M-Bloc Shaft Liner may be substituted for American Gypsum’s standard 1” Shaft Liner panels. Lightweight non-load bearing gypsum Shaftwall systems have replaced traditional masonry for interior vertical enclosures including stairwells, elevator enclosures and mechanical chases.

American Gypsum’s M-Bloc Shaft Liner has been approved for use in the following assemblies:

- U375 - 2 Hour H-Stud Area Separation Wall System

- V455 - 1 & 2 Hour Shaftwall Systems using I, C-H and C-T Studs

- U428 - 2 Hour Shaftwall System using C-H and C-T Studs

- U429 - 2 Hour Area Separation Wall System using C-H and C-T Studs

- U529 - Laminated Wall System

Greenguard

M-Bloc Shaft Liner gypsum wallboard has achieved UL Environment’s GREENGUARD GOLD Certification. GREENGUARD Certified products are scientifically proven to meet some of the world’s most rigorous, third-party chemical emissions standards, helping reduce indoor air pollution and the risk of chemical exposure while aiding in the creation of healthier indoor environments. For more information, visit www.ul.com/gg. To obtain product certificate, please select the GREENGUARD link to the right.

Product Data

Sizes

| Thickness | Widths | Lengths | Edge Types |

|---|---|---|---|

| 1" (25.4mm) | 2' (610mm) | 8' - 14' (2438mm - 4267mm) | Double Beveled |

Special lengths or edges may be available on special order. Consult your American Gypsum sales representative for details.

Technical Data

Storage and Handling

Gypsum board does not generate or support the growth of mold when it is properly transported, stored, handled, installed, and maintained. However, mold spores are present everywhere and when conditions are favorable; mold can grow on practically any surface. GYPSUM BOARD MUST BE KEPT DRY to prevent the growth of mold.

Gypsum board must be stored in an area that protects it from adverse weather conditions, condensation, and other forms of moisture. Job site conditions that can expose gypsum board to water or moisture must be avoided.

Gypsum board must be protected during transit with a weather-tight cover in good condition. Plastic shipping bags are intended to provide protection during transit only and must be promptly removed upon arrival of the load. Failure to remove the shipping bag can increase the likelihood of developing conditions favorable to the growth of mold.

Gypsum board that has visible mold growth must not be used.

Gypsum board must be stored off the ground and under protective cover. Sufficient risers must be used to assure support for the entire length of the wallboard to prevent sagging.

Gypsum board must be delivered to the job site as near to the time it will be used as possible. Individuals delivering gypsum board to jobsites should ensure that it is carried, not dragged, to place of storage/installation to prevent damage to finished edges.

Gypsum board shall always be stacked flat - NEVER on edge or end. Gypsum board stacked on edge or end is unstable and presents a serious hazard should it accidentally topple. Gypsum board should be placed so weight is evenly distributed and the floor is not overloaded.

Applicable Standards

| Mold Resistance | Score of 10 (ASTM D 3273) |

|---|---|

| Manufacturing | ASTM C 1396 section 6 (C 442) Federal Specification – SS-L-30D Type IV Grade X |

| Installation | ASTM C 840 Gypsum Association GA-216 Gypsum Association GA-214 Gypsum Association GA-620 |

| Surface Burning Characteristics | ASTM E 84 Flame Spread 0 Smoke Developed 0 |

LEED Contributions

Our products can contribute to the following credits within the Materials and Resources (MR) category.

- LEED MR Credit 2: Construction Waste Management

- LEED MR Credit 4: Recycled Content

- LEED MR Credit 5: Regional Materials

Our products can contribute to the following credit within the Indoor Environmental Quality (IEQ) category.

- LEED IEQ Credit 4.6: Low-Emitting Materials - Ceiling and Wall Systems (SCHOOLS ONLY)

To learn more please click the LEED link at right.

Related Links

SDS ecoScorecard LEED CSI 3 Part Spec GREENGUARD Certification Limited WarrantyWhere to Buy?

Call (866) 439-5800 or Send Email